In CNC machining, accuracy depends on more than sharp tools and precise programming—it’s also about how securely your workpiece and tooling are held. Clamping pressure plays a critical role in maintaining stability throughout the machining process. Too little pressure can cause parts to vibrate or shift mid-cut, while too much can deform delicate materials or damage the tooling assembly.

Finding the right balance ensures that every cut is smooth, consistent, and within tolerance. By understanding how clamping force works and learning to adjust it properly, machinists can improve surface finish, extend tool life, and protect both their parts and equipment.

The Connection Between Clamping Force and Machining Accuracy

Every time you run a CNC job, your machine exerts cutting forces on the tool and the part. Clamping pressure counteracts those forces, holding everything firmly in place. If clamping pressure isn’t correctly applied, even the most precise machine will struggle to maintain dimensional accuracy.

Under-clamping allows the workpiece or tool to shift during machining, leading to chatter, poor surface finish, and dimensional errors. Over-clamping, on the other hand, can distort the part—especially thin-walled or soft materials—resulting in out-of-spec dimensions that can’t be fixed with a finishing pass.

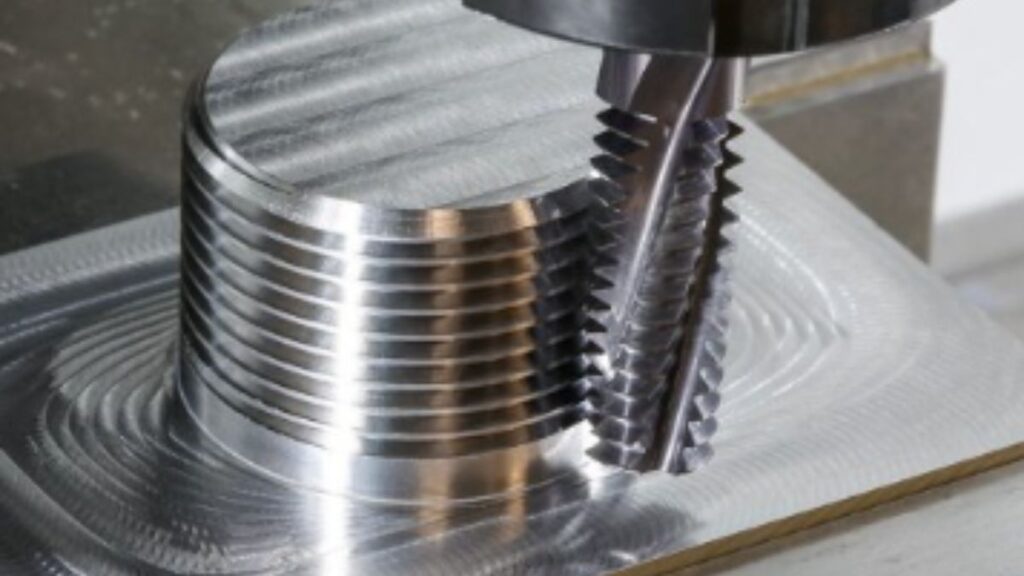

The ideal clamping force depends on several factors: material type, cutting speed, depth of cut, and tool geometry. A properly calibrated ER collet system ensures consistent, concentric clamping around the tool shank, minimizing runout and vibration. High-quality collets apply even pressure along the circumference, keeping the tool securely seated without over-compressing it.

Vibration is one of the most common side effects of poor clamping. When the tool or part moves slightly during cutting, it causes inconsistent chip load, uneven wear, and heat buildup. Over time, this can dull the cutting edge, shorten tool life, and leave visible tool marks on the surface. Stable clamping eliminates these variables, allowing the spindle to perform at maximum efficiency.

Accurate clamping also improves repeatability. In production environments where multiple parts are machined consecutively, maintaining consistent clamping force ensures each part meets the same dimensional tolerances. Without that consistency, even minor variations in pressure can result in measurable differences between parts—an issue that adds up quickly in high-volume manufacturing.

How to Adjust Clamping Pressure for Better Part Quality

Getting clamping pressure right requires a combination of proper equipment, technique, and maintenance. Here’s how to optimize it for precision and longevity:

- Use the correct clamping system for your tool.

Different applications require different holders. Collets, hydraulic chucks, and shrink-fit holders all provide unique benefits. Collets are versatile and ideal for general machining, while hydraulic chucks offer superior damping for high-speed work. Always match your holder to the tool and operation type. - Maintain your clamping components.

Dirty or worn components can reduce clamping efficiency. Chips, oil, or dust trapped inside a holder can prevent uniform contact between surfaces, leading to uneven grip or runout. Clean collets, nuts, and holders regularly to keep them performing like new. - Torque tools to manufacturer specifications.

Over-tightening can deform collets or strip threads, while under-tightening can cause slippage. Always use a torque wrench set to the correct value for your holder type. This ensures consistent clamping pressure across all setups. - Monitor tool wear and vibration.

If you notice increasing vibration, noise, or tool deflection, it could indicate improper clamping. Adjusting pressure or re-seating the tool can often resolve these issues before they affect part quality. - Match pressure to material type.

Soft materials like aluminum or plastics require gentler pressure to prevent distortion, while harder materials can handle higher clamping forces. Fine-tuning this balance helps maintain part integrity and dimensional accuracy.

When performing intricate operations such as thread milling, stability becomes even more important. A secure setup ensures that your thread milling cutter maintains perfect alignment throughout each pass, producing clean, accurate threads without chatter. Inconsistent pressure can cause pitch errors, damaged threads, or broken tools.

- Inspect your toolholders regularly.

Wear in tapers or collet seats can reduce grip and cause micro-movements during cutting. Periodic inspection helps identify these issues early, maintaining the precision your parts require. - Use balanced tool assemblies for high-speed machining.

At higher spindle speeds, imbalance magnifies. Balanced holders reduce vibration and distribute clamping forces evenly, which helps maintain accuracy and prolong spindle life.

High-quality CNC lathe tool holders are designed to withstand repeated clamping cycles without losing accuracy. Their rigidity and stability make them ideal for heavy-duty applications, providing dependable grip and smoother cutting action.

The Benefits of Proper Clamping

When clamping pressure is correctly set and maintained, the results are immediately noticeable:

- Improved part accuracy: Parts stay within tight tolerances even during aggressive cuts.

- Better surface finish: Reduced vibration leads to smoother, cleaner surfaces.

- Longer tool and spindle life: Stable setups prevent deflection and wear.

- Faster production: Secure clamping allows for higher feed rates and reduced cycle times.

- Reduced scrap and rework: Consistency minimizes dimensional errors across production runs.

Proper clamping is one of the simplest ways to elevate machining precision. It bridges the gap between high-performance tools and the accuracy your customers demand.

Final Thoughts

Clamping pressure might seem like a small detail, but it has a huge impact on your CNC results. Too much or too little pressure can ruin an otherwise perfect setup. By using quality ER collets, keeping holders clean, and calibrating torque correctly, you’ll maintain alignment, stability, and accuracy from the first cut to the last.

When every thousandth of an inch counts, mastering clamping pressure ensures you get the most out of your machine—and every part that leaves your spindle meets your highest standards.