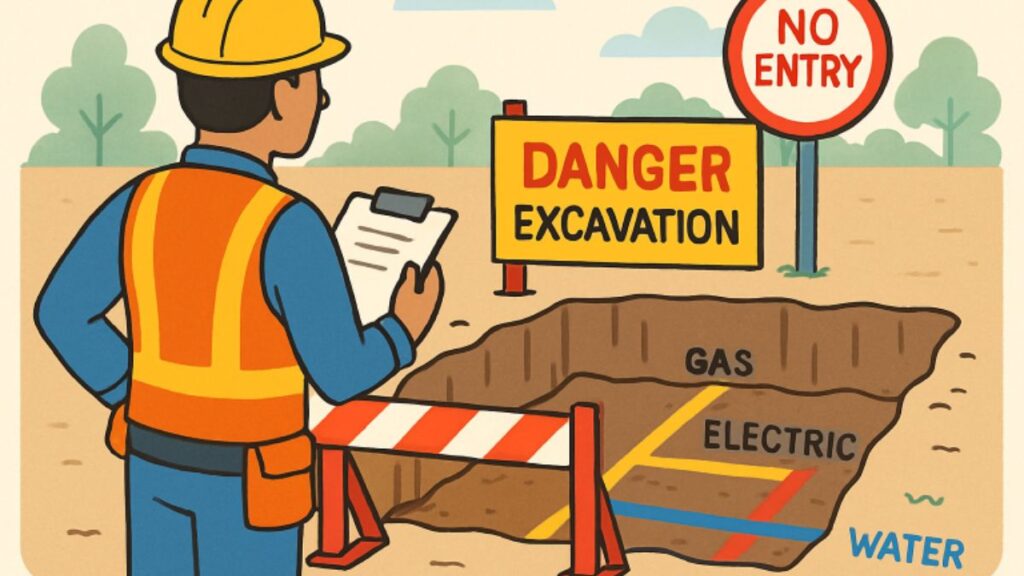

Understanding Excavation Hazards

Excavation projects pose unique dangers that affect not only workers but also the property itself. Cave-ins remain the leading cause of fatalities in excavation work. Unexpected encounters with underground utilities can result in injury, property damage, or significant service disruptions. Additional hazards include being exposed to contaminated atmospheres and falling materials from above. Becoming aware of these hazards forms the foundation for a safer job site. For those looking for local expertise, trusted land excavation services Birmingham, AL offer in-depth knowledge of safe excavation practices tailored to your region.

Preventing these risks requires not just compliance with regulations but fostering a culture of diligence and awareness throughout every stage of the project. Making excavation safety a top priority translates directly into fewer accidents and a smoother workflow.

Pre-Excavation Planning and Site Assessment

Adequate planning is non-negotiable before any digging commences. One of the first steps is contacting your local utility locator, such as by dialing 811 in the United States. This step ensures that all underground lines for gas, electricity, water, communications, and more are marked, significantly reducing the likelihood of dangerous, costly utility strikes. Knowing exactly what lies below the surface is essential to avoid emergencies and maintain progress on schedule.

Soil stability is another critical aspect often overlooked. Conducting a thorough soil analysis helps identify the soil type, Type A, B, or C, each of which requires specific measures to reinforce and support the excavation sides. Unstable soil conditions, especially in wet or loose areas, necessitate more robust protective systems to prevent harmful cave-ins. Lastly, the weather can change site conditions quickly. Monitoring forecasts and postponing work during heavy rain or extreme events helps protect both workers and the structural integrity of excavations.

Implementing Protective Systems

Once work begins, utilizing protective systems is vital. Three main strategies keep excavation sites secure. Sloping and benching involve cutting back trench walls at safe angles or creating steps. This technique helps prevent soil from collapsing inwards. Shoring means adding supports, such as hydraulic or timber braces, to prop up the sides of the excavation. Shielding, using trench boxes or other devices, creates a safe space for workers to operate even if a nearby collapse occurs. Each approach must match the soil conditions and project requirements to ensure effectiveness.

Ensuring Safe Access and Egress

Safe entry and exit routes are a legal and practical requirement for trenches deeper than four feet. Providing ladders, ramps, or stairways within 25 feet of all personnel allows for a prompt evacuation if hazards arise. These paths must remain clear and unobstructed during all work hours. Employers should regularly inspect and maintain access equipment to keep it secure and functional.

Monitoring Atmospheric Conditions

Some excavations expose workers to confined spaces or hazardous atmospheres, especially with deep or urban utility projects. Testing the air for oxygen deficiency, combustible gases, or toxic substances is essential before and during work. If dangerous conditions are found, proper ventilation, continuous monitoring, and Personal Protective Equipment (PPE) are necessary to maintain safety standards. Protecting workers from these invisible dangers helps prevent sudden illness or fatalities from exposure.

Training and Communication

Effective training programs prepare workers for the array of risks associated with excavation. Education must cover hazard recognition, proper equipment usage, and emergency procedures. Training should be refreshed frequently and tailored to address unique site-specific hazards. Strong communication, whether through regular meetings or digital alerts, ensures that everyone is informed of changes, incidents, and roles in the event of an emergency. Implementing a buddy system can also increase accountability and vigilance on-site.

Regular Inspections and Maintenance

Assigning a competent person to perform daily site inspections is a regulatory requirement outlined by OSHA and other safety organizations. This individual is responsible for identifying signs of instability, equipment malfunctions, or changing weather that could jeopardize safety. Inspections must be intensified after storms or seismic activity. All protective measures and machinery must be kept in top working order, with inspection records maintained as part of project documentation.

Emergency Preparedness

Despite taking all precautions, accidents can still happen. Developing a tailored emergency action plan is crucial for excavation sites. Plans should define clear procedures for cave-ins, utility damage, or injuries, and ensure all workers know how to respond quickly. Frequent drills increase confidence and lower response times in the event of a real emergency. Proactively planning for the unexpected is a hallmark of professional excavation management.

Final Thoughts

By following these essential safety tips and maintaining a proactive risk-management approach, property owners, contractors, and work crews can dramatically reduce the likelihood of accidents. Not only does this protect those on-site, but it also safeguards the project’s progress and the surrounding property from preventable harm.