Introduction to Prefabricated Log Homes

Prefabricated log homes are revolutionizing how people approach the rustic dream of cabin living, blending the ageless beauty of wood with the efficiency of modern construction. These homes stand out for their ability to deliver timeless log cabin comfort, but with faster build times and greater reliability, prefabricated log homes offer a remarkable solution that meets both design dreams and practical needs, combining the warmth and charm of traditional architecture with the advantages of precision engineering.

Unlike conventional stick-built houses or kit cabins assembled entirely on-site, prefabricated log homes arrive as expertly crafted sections. These carefully manufactured and rigorously inspected components are ready for swift assembly, saving time and reducing common complications on the job site—while still offering the customizable appeal that log home enthusiasts love.

Design and Planning

The journey to building a prefabricated log home begins with thorough planning and smart design choices. Homeowners typically work alongside architects and skilled designers to develop blueprints that embody their unique style, family needs, and plans. This phase is more than an exercise in creativity—it involves balancing your vision with building codes, local environmental factors, and energy efficiency goals.

Today’s advanced digital tools allow homeowners and builders to virtually tour their designs, refining everything from traffic flow to kitchen window size. This collaborative approach ensures that every detail is custom-fitted to your lifestyle and site conditions by the time you approve the final plans. Thoughtful design early on streamlines every downstream step, resulting in a predictable and low-stress build.

Manufacturing the Components

After the design is finalized, your vision is brought to life in physical form at the factory. High-quality logs—often sourced locally and sustainably—are carefully selected for their strength and beauty. The manufacturing process uses skilled craftsmanship and state-of-the-art machinery to treat and cut each log to precise specifications. This maximizes the integrity and fit of every piece, reducing unnecessary waste and strengthening your home’s sustainability credentials.

Quality Control Measures

Each component undergoes multiple stages of quality control before shipping. Inspectors assess every log to confirm structural soundness, proper seasoning, and exact measurements. Additional checks verify that treatments—such as anti-decay and pest-resistant finishes—have been uniformly and correctly applied. Stringent quality assurance at this stage ensures that when assembly begins, each piece interlocks seamlessly with the next, resulting in a solid and durable finished structure.

Site Preparation

While the components are being manufactured off-site, site preparation work kicks off. The land is cleared, graded, and leveled to establish a dependable building platform. Foundations—ranging from traditional concrete slabs to elevated pier systems—are formed to match the home’s precise footprint. Running utilities (water, electricity, and septic or sewer lines) are frequently completed during this stage, ensuring a smooth transition to the assembly phase. Proper preparation here is crucial to guarantee the longevity and energy efficiency of the finished home.

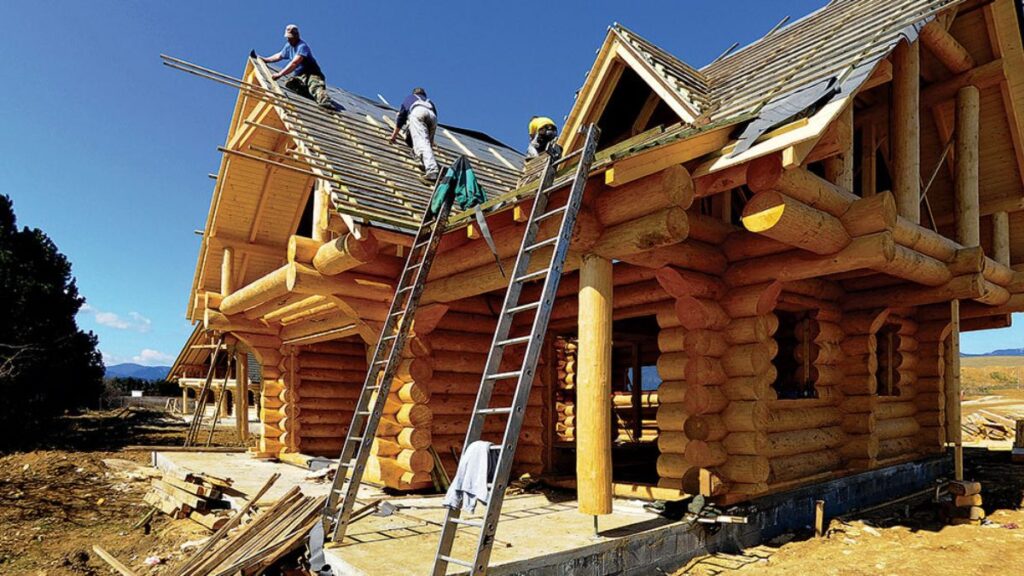

Delivery and Assembly

Once your site is ready and the prefabricated components arrive, the on-site build can commence. The process starts with the foundations, followed rapidly by the wall sections, roofing systems, and, finally, the installation of doors and windows. This step is significantly faster and more predictable than traditional construction due to the precision cutting and labeling at the factory. A typical log home assembly may take weeks instead of months, substantially reducing the risk of costly weather delays.

Finishing Touches

After the main structure is in place, attention shifts to insulation, wiring, plumbing, and interior finishes. Modern prefabricated log homes can be equipped with energy-saving features, including high-performance windows, advanced HVAC systems, and solar panels. Walls can be stained or painted to your taste, and custom cabinetry or specialty fixtures can be added for a truly personalized living space. These finishing steps transform a technically sound structure into a comfortable, warm, inviting home.

Benefits of Prefabricated Log Homes

Prefabricated log homes offer a host of advantages, making them a compelling choice for many different homeowners:

- Efficiency: Construction is completed more rapidly since most work is done off-site, minimizing on-site delays.

- Cost-Effectiveness: Labor costs are significantly reduced, and there is far less waste of materials due to precise pre-cutting and planning.

- Quality Assurance: Factory assembly guarantees consistent conditions and higher reliability than variable job site environments.

- Sustainability: The manufacturing process uses raw materials judiciously, limits waste, and frequently sources logs from sustainably managed forests.

Conclusion

By blending careful design, precise manufacturing, and rapid on-site assembly, prefabricated log homes are an appealing alternative to traditional construction methods. Homeowners enjoy all the tactile pleasures of classic log cabins—rich wood grain, robust structures, and cozy interiors—without months on a noisy build site. As more people seek eco-friendly, cost-efficient paths to custom homes, these models are only growing in popularity.