Automated CNC technology has emerged as a driving force in transforming modern workshops, ushering in a new era of manufacturing where speed, precision, and efficiency are paramount. Workshops that have embraced Computer Numerical Control and automation are now leading the charge toward smarter, more productive, and scalable operations. In this rapidly shifting environment, forward-thinking companies are leveraging advancements to outperform traditional workflows and reduce bottlenecks. Modern innovators like Phantom CNC Systems enable workshops to deploy flexible, intelligent solutions that meet the ever-increasing demands of today’s manufacturing challenges. Automation is transforming production lines into interconnected systems that enhance productivity and quality, which are crucial for industries such as aerospace, automotive, and medical device manufacturing. This shift in CNC (Computer Numerical Control) automation has resulted in significant cost savings and improved product standards, allowing smaller manufacturers to compete with larger firms. The advancement enables high-mix, low-volume shops to achieve precision engineering, mass customization, and continuous operations, helping businesses maintain competitiveness and ensure future success.

Automation in CNC Machining

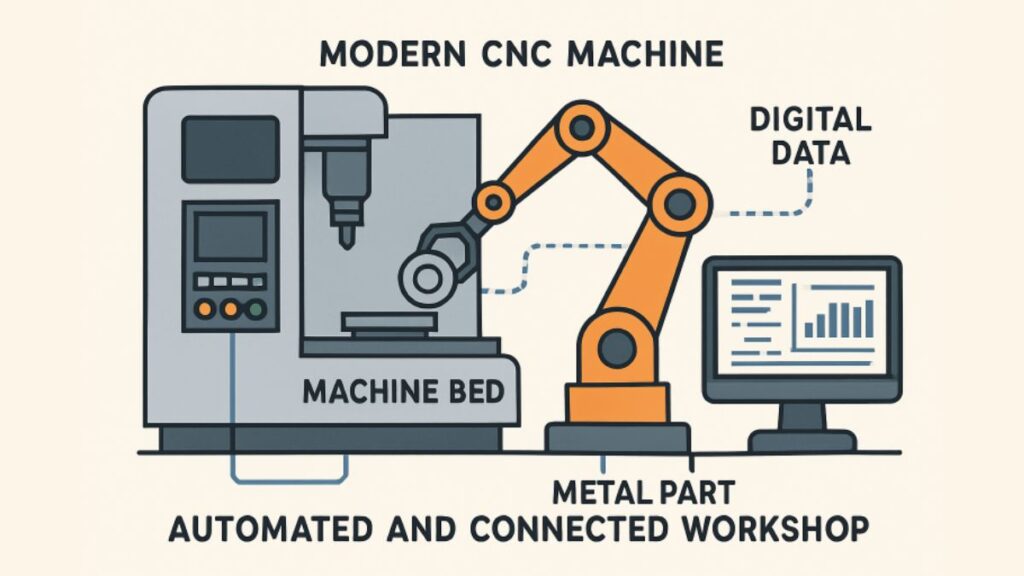

Recent innovations in CNC machining have shifted automation from a luxury for large manufacturers to a necessity for shops of all sizes. Today’s automated workflows manage everything from robotic arms feeding raw materials into the machine to networked sensors that track spindle loads and tool wear in real time. By integrating such systems, manufacturers facilitate uninterrupted, 24-hour production, slashing lead times and boosting both throughput and reliability. A case in point is a UK-based workshop that reduced its delivery times by 40% by implementing robotic loading technologies. Not only does this translate into greater output, but it also ensures that human talent is refocused on high-value tasks, design, quality assurance, and creative problem-solving, rather than repetitive manual labor. These shifts have proven instrumental for manufacturers competing in demanding sectors where timeliness and quality are paramount.

AI Integration Enhancing Precision

Artificial intelligence is enhancing CNC machining by optimizing processes through real-time data analysis. AI algorithms optimize cutting paths and dynamically adjust speeds, maximizing tool life and reducing scrap rates. This capability allows machines to respond to changes in material and cutting conditions, maintaining precise tolerances and excellent surface finishes. Machine learning also predicts failures and schedules maintenance, minimizing downtime, a crucial factor in industries like medical device manufacturing. Overall, these advancements lead to more efficient production of high-quality parts, allowing operators to focus on optimization rather than troubleshooting.

IIoT and Smart Factories

The Industrial Internet of Things (IIoT) is the backbone behind the new generation of smart factories, unlocking levels of connectivity and agility that traditional workshops could never attain. With sensor-rich machines sending real-time data to centralized dashboards, manufacturers can now oversee production, monitor health metrics, and conduct diagnostics from anywhere in the world. This always-on feedback loop allows for remote troubleshooting, and actionable adjustments can be made in real time without halting the entire production line. The IIoT’s data-driven approach not only reduces operational costs but also enhances quality control by flagging and correcting anomalies before defective parts ever leave the facility. As the digital thread weaves through every stage of production, IIoT integration positions workshops to adapt quickly to disruptions and evolving customer demands, reinforcing their resilience and operational excellence.

Real-World Examples of Automation

Across North America, small and mid-sized CNC shops are proving that automation is within reach for businesses at every scale. For example, an Ohio-based manufacturer implemented collaborative robots alongside five-axis CNC machines, achieving a 25 percent reduction in setup times and a 15 percent lift in productivity, all without downsizing their workforce. In these environments, automation does not displace employees; instead, it allows them to transition from repetitive machine feeding to value-rich roles in programming, process optimization, and project management. Likewise, industries ranging from aerospace to custom automotive find that robotic systems not only speed up production but also raise the bar on repeatability and overall quality. These stories are no longer outliers; they illustrate the new standard in machining excellence, where precision-engineered systems drive better business outcomes and more rewarding careers for skilled workers.

Benefits of Automated CNC Systems

Automated CNC systems enhance speed and efficiency by enabling continuous workflows, significantly reducing turnaround times. The integration of robotics enables faster order delivery, while AI-driven monitoring ensures precision and consistency in manufacturing, minimizing the risk of critical failures from even small deviations. Cost reductions are evident through reduced waste, improved use of raw materials, and reduced unplanned downtime, with some shops achieving annual operational savings of over 18 percent. Additionally, automation improves worker safety by handling dangerous tasks, leading to increased job satisfaction and the opportunity for employees to engage in supervisory and technical roles.

Challenges and Considerations

The road to automation is not without challenges. High upfront investment in equipment and integration can present barriers for small to mid-sized manufacturers. Additionally, operators and technicians require specialized training to manage, maintain, and troubleshoot sophisticated automated systems. Organizational resistance to process change and the need to maintain cybersecurity across the digital ecosystem are real concerns. Protecting sensitive designs and intellectual property from cyber threats is increasingly critical as more factories become interconnected. Manufacturers must strategically plan their transition, ensuring workforce upskilling, data integrity, and systems resiliency.

Future Trends in CNC Automation

The future of CNC automation is driven by rapidly advancing technologies, such as digital twins and increasingly sophisticated AI models. The adoption of digital twins, virtual replicas of physical systems, enables simulation, testing, and refinement of production processes before touching the shop floor. This minimizes trial-and-error, reduces waste, and allows manufacturers to pivot quickly to new product designs or market shifts. With increasing automation and digitization, workshops will be able to offer mass customization and ultra-efficient just-in-time manufacturing. The continued rise of cloud data analytics and machine-to-machine communication is set to further enhance quality, flexibility, and profitability in the years ahead.

Conclusion

The impact of automated CNC technology on modern workshops is profound and irreversible. By integrating automation, AI, and IIoT, manufacturers are achieving unprecedented heights in productivity, precision, and adaptability. Those willing to embrace change and invest in the right systems will not only survive but thrive in the fast-paced world of modern manufacturing. Staying informed about these advances, investing in workforce development, and aligning with technology leaders will be essential for any shop aiming to maintain its edge in this era of industrial transformation.