Introduction

Effective pipeline maintenance is essential for reliable and safe resource transport systems. Energy and resource pipelines often span many miles across diverse terrains, confronting a range of environmental, mechanical, and operational stresses. With careful attention to inspection and technology integration, companies can not only enhance efficiency but also prevent hazardous events and operational downtime. Stakeholders rely on pipeline infrastructure for everything from daily gas needs to crucial industrial processes, making reliability paramount. One of the most crucial components of a robust maintenance strategy involves using pipeline pigs for natural gas systems, which enable both cleaning and in-line inspections to ensure optimal functionality and safety. These specialized devices are instrumental in minimizing the risk of build-ups that may otherwise impede pipeline flow or cause system failures.

Pipeline operators face increasing pressure to minimize failures and prolong infrastructure lifespan, as regulatory scrutiny and environmental expectations intensify. This heightened oversight stems from past accidents and a growing public demand for safer practices and transparency. Comprehensive adoption of industry best practices, in conjunction with tools like pipeline pigs for natural gas systems, promotes operational reliability while minimizing costly repairs and environmental impacts. Furthermore, a well-maintained pipeline reduces the likelihood of major environmental events, such as spills or leaks, ensuring that companies remain in good standing with their communities. Embedded in every stage of maintenance, these best practices support the sustainable growth of energy and resource networks, ultimately contributing to the overall resilience of the energy sector.

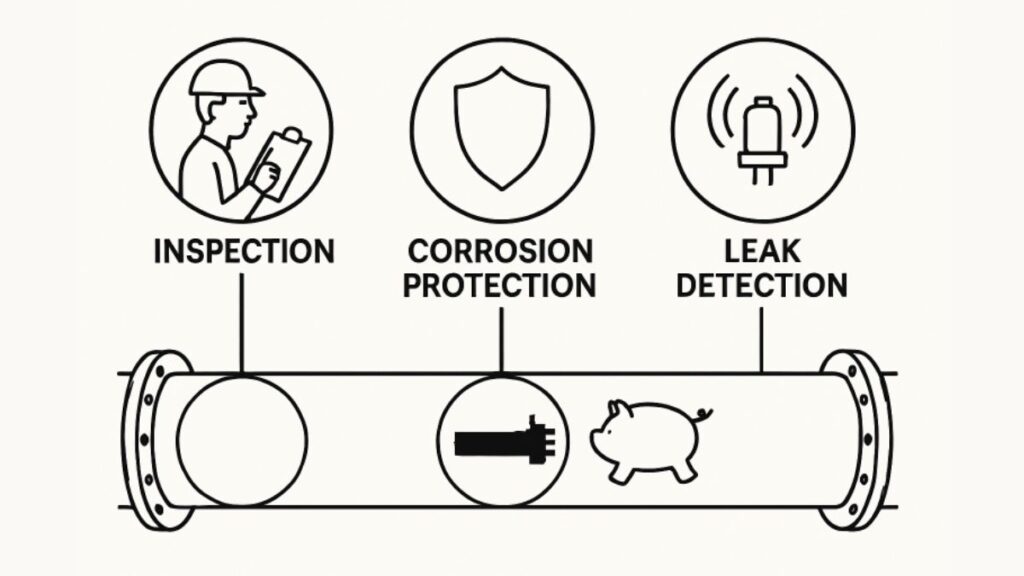

Regular Inspections

Routine inspections are fundamental for identifying minor defects before they escalate into major issues. Inspection routines are the backbone of preventative maintenance, offering opportunities to detect corrosion, structural weaknesses, or external damage from third-party activity. The advent of technologies such as unmanned aerial vehicles (UAVs) equipped with advanced sensors and AI-driven detection software enables operators to monitor pipelines efficiently and reach difficult locations. Using UAVs and high-resolution imaging, companies can perform broad sweeps over remote or inaccessible areas, identifying vegetation encroachment, line exposure, or signs of tampering without endangering staff. These innovations provide real-time data, reducing inspection costs and improving safety by lessening the need for manual intervention in hazardous areas. The National Transportation Safety Board (NTSB) emphasizes implementing Pipeline Safety Management Systems (PSMS) to enhance safety and encourage early intervention in aging infrastructure. This continuous oversight is a key element in reducing accident rates and reinforcing a culture of proactive maintenance.

Corrosion Control

Corrosion represents a leading cause of pipeline deterioration and failure worldwide. Different sections of a pipeline, depending on the material and local environment, will experience varying levels of susceptibility to corrosion. Utilizing corrosion control systems, such as applying protective coatings and implementing cathodic protection, plays a key role in reducing degradation rates. Protective coatings act as the first defense, while cathodic protection works by applying an electrical current to counteract the chemical reactions causing corrosion. Monitoring systems that measure environmental factors—like soil composition and moisture—provide invaluable insights, allowing for timely adjustments and extended lifespan of assets. By incorporating continuous corrosion monitoring, operators are better equipped to spot small problems and implement corrective measures before they escalate. Proactive corrosion control is vital for energy companies as it directly impacts the long-term sustainability and safety of their infrastructure, preventing unplanned downtime and costly repairs that can affect profitability and community trust.

Leak Detection Systems

Integrating sophisticated leak detection systems, such as acoustic monitoring technologies and pressure sensors, is essential. Rapid leak detection helps operators contain incidents quickly, reducing environmental and financial consequences. These systems enable quick identification of anomalies and leaks, thus limiting environmental harm and reducing repair expenses. Modern leak detection networks utilize a combination of fiber optic sensors, digital twins, and satellite imagery, providing round-the-clock supervision of pipeline assets. Enhancements via machine learning algorithms can further increase the accuracy and speed of detection, contributing to safer and more responsive pipeline operations. Automated alerts triggered by intelligent software assist personnel in analyzing situations rapidly and deploying resources where needed most. The U.S. Department of Transportation highlights leak detection systems as a principal safeguard for community health and environmental protection. Regular audits and updates ensure that these systems remain current with developing threats and new compliance mandates.

Pigging Operations

Pigging is a vital process involving specialized devices—referred to as “pigs”—that travel inside pipelines to perform cleaning, inspection, and maintenance functions. The role of pigging extends beyond basic cleaning, as intelligent pigs can now collect real-time data on wall thickness, metal loss, and internal obstructions. Regular pigging helps prevent blockages, corrosion, and deposits that may impair flow or trigger failures. Pigging ensures product quality and system efficiency by maintaining a steady flow and removing potential buildup from inside pipeline walls. Leveraging predictive analytics through machine learning not only optimizes pig schedules but also reduces operational costs by identifying periods of highest risk. This optimization results in more effective allocation of maintenance budgets and less disruption to normal operations. Modern pigging devices can collect internal data and contribute to the precision of preventative maintenance programs, informing operators of developing issues before they become threatening. The future of pigging will likely involve greater automation and integration with centralized data systems to enhance real-time response capabilities.

Staff Training

The continuous education and training of maintenance personnel are imperative for ensuring adherence to the latest safety standards and technological advancements. A well-trained staff is more adept at recognizing operational risks and responding promptly to emergencies. Comprehensive training programs should equip staff with the knowledge to operate new digital tools, understand evolving regulations, and identify early warning signs of pipeline failure. Regular workshops, certification courses, and hands-on simulations help keep crews informed on new technologies and safety protocols. Effective training also fosters a culture of safety and vigilance, paramount in preventing costly incidents. Companies that invest in staff development often see a reduction in lost time due to incidents and an overall improvement in work quality and employee morale.

Emergency Response Plans

A well-maintained emergency response plan is essential to mitigate the impact of unexpected incidents. These plans must be clear, organized, and accessible, laying out steps for actions in response to fires, leaks, spills, or third-party intrusions. These plans should be detailed, scenario-specific, and regularly updated to address evolving threats and regulatory changes. Collaboration with local authorities and first responders, as well as public awareness campaigns, enhances preparedness and response capabilities for all parties involved. Conducting regular emergency drills and involving all stakeholders ensures that everyone knows their role during an incident, thereby facilitating swift and effective action to protect both the public and the environment. Periodic plan reviews help incorporate lessons learned from drills or past events, creating a continuous improvement cycle.

Technological Advancements

Adopting cutting-edge technologies—such as machine learning, deep data analytics, and reinforcement learning—has revolutionized pipeline maintenance. Modern pipelines often embed sensors and IoT devices, collecting real-time information about temperature, pressure, vibration, and chemical composition. By processing massive datasets, these technologies identify risk patterns and enable predictive interventions, which minimize the likelihood of failures. Predictive maintenance, enabled by artificial intelligence, reduces unexpected downtime and allows for more strategic deployment of maintenance resources. As the utility industry evolves, continuous investment in research and development remains critical for future-proofing pipeline systems and meeting rising regulatory standards. Technology also improves remote monitoring and automated maintenance processes, increasing efficiency and ensuring compliance with increasingly stringent oversight.

Regulatory Compliance

Strict adherence to regulatory standards—such as those issued by PHMSA and other international bodies—is non-negotiable in the pipeline sector. As regulations evolve to address new safety, environmental, and cybersecurity concerns, companies must remain vigilant in updating policies and procedures. Compliance ensures not only legal operation but also establishes trust with the public and stakeholders. Proactive communication with regulators and the public enhances transparency and reduces the risk of reputational damage following an incident. Regular audits, transparent reporting, and proactive engagement with regulatory updates are essential practices for maintaining compliance and operational integrity. By embedding regulatory compliance into company culture and day-to-day routines, pipeline operators position themselves for long-term success and public trust.