Introduction

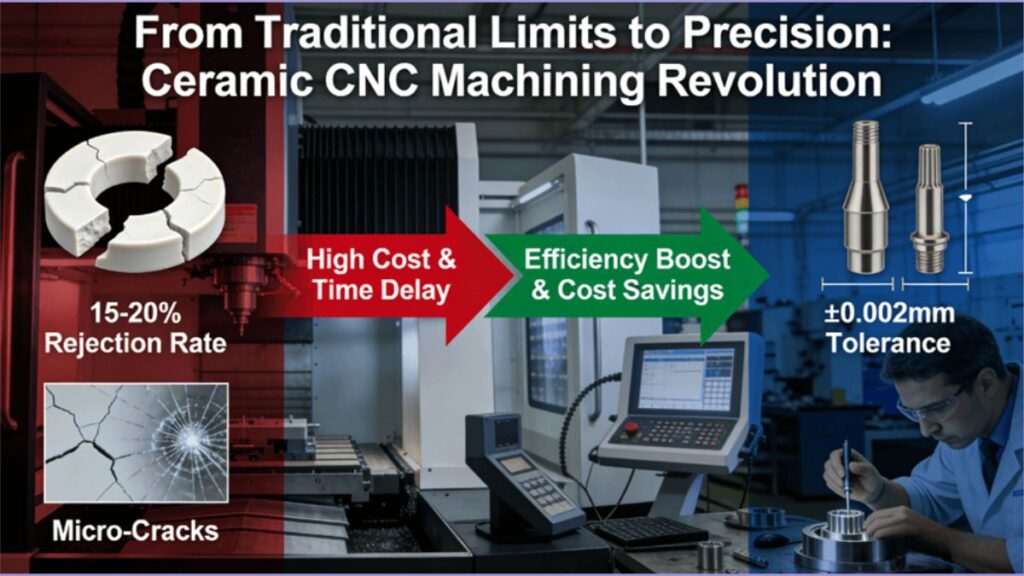

In high-tech manufacturing, traditional ceramic processing methods like manual grinding often lead to high rejection rates (15-20%), micro-cracks, and extended lead times, severely limiting the production of precision ceramic components for aerospace and medical applications. The fundamental challenge lies in the inherent brittleness and extreme hardness of advanced ceramics, which conventional CNC technologies struggle to machine consistently. This results in hidden defects and unreliable performance.

This article examines how advanced Ceramic CNC Machining leverages digital precision control, specialized tooling, and rigorous quality protocols to achieve micron-level accuracy (±0.002mm), enhance reliability, and reduce costs. Referencing standards like ISO 9001 and leveraging insights from organizations like NIST on smart manufacturing trends, we provide a systematic framework for engineers to overcome these persistent limitations. The following sections break down the technical principles, applications, and optimization strategies that make this approach transformative.

What is Ceramic CNC Machining and How Does It Differ from Conventional Processes?

Ceramic CNC Machining represents a paradigm shift from traditional methods, combining computer-controlled precision with specialized diamond tools to achieve material removal at the micron level. This digital manufacturing approach eliminates the variability inherent in manual processes.

1. The Principles of Digital Material Removal

Unlike conventional grinding which relies on abrasive contact, Ceramic CNC Machining uses precisely engineered diamond-coated end mills and drills operating at high spindle speeds (often exceeding 30,000 RPM). The process involves micrometer-level precision where each cutting path is digitally programmed to control depth of cut, feed rate, and tool engagement. This level of control minimizes subsurface damage and micro-cracks that plague traditional methods. According to NIST’s smart manufacturing guidelines, this digital thread connects design to production, ensuring repeatable outcomes even for the most complex geometries.

2. Contrasting Conventional and Digital Approaches

Traditional ceramic machining depends heavily on operator skill and often involves multiple setups, leading to cumulative errors that can exceed 0.1mm. In contrast, the CNC machining process for ceramics maintains a single datum throughout production, reducing positional errors by up to 80%. For instance, in manufacturing alumina insulator components, the digital approach improved feature location accuracy from ±0.05mm to ±0.01mm. This systematic methodology transforms ceramics from difficult-to-machine materials into viable options for precision components.

3. Technological Enablers and Innovation

The availability of specialized diamond tooling with optimized geometries for specific ceramic materials has been crucial to this advancement. When combined with high-pressure coolant systems that prevent thermal shock and effectively remove microscopic chips, tool life can be extended by 300% compared to conventional dry grinding. This combination of advanced tooling and process control represents a fundamental advancement in ceramic manufacturing capabilities.

What Are the Key Advantages of Using CNC Machining for Ceramics?

The transition to digitally-controlled ceramic machining offers substantial benefits across dimensional accuracy, component performance, and total cost of ownership, making it particularly valuable for high-reliability applications.

1. Unprecedented Precision and Geometrical Freedom

Ceramic CNC Machining achieves tight tolerances of ±0.002mm routinely, enabling the production of complex features like thin walls (down to 0.3mm), deep cavities, and true-position holes that are impossible with conventional methods. This geometric capability unlocks new design possibilities for engineers working on advanced components. In optical applications, for example, this precision enables the creation of freeform ceramic lens mounts with surface finishes better than Ra 0.2μm, eliminating the need for secondary polishing operations.

2. Enhanced Component Performance and Reliability

The superior surface integrity achieved through controlled CNC machining directly translates to improved component performance. Medical implant manufacturers report 30% longer service life for ceramic orthopedic components due to the absence of surface and subsurface damage that can initiate failure. The exceptional temperature resistance and corrosion immunity of precisely machined ceramics make them ideal for aerospace applications where components must withstand extreme environments while maintaining dimensional stability.

3. Economic Benefits and Waste Reduction

While initial tooling costs are higher, the total cost reduction over the product lifecycle can reach 40% through several mechanisms. The dramatic reduction in scrap rates (from 15-20% to under 3%), combined with faster production cycles and minimized secondary operations, delivers substantial savings. Additionally, the ability to consolidate assemblies into single ceramic components eliminates multiple part numbers and associated inventory costs.

H2: Where is Ceramic CNC Machining Applied in High-Tech Industries?

The unique combination of properties offered by precision-machined ceramics has led to their adoption across multiple high-technology sectors where conventional materials reach their performance limits.

l Aerospace and Defense Applications: In aerospace, ceramic components provide thermal protection systems for hypersonic vehicles, withstanding temperatures exceeding 1600°C while maintaining structural integrity. Nozzle guides, radomes, and thermal barrier components machined from silicon nitride or zirconia offer 5-8 times better performance in extreme environments compared to superalloys. The shift to Ceramic CNC Machining has enabled the production of these components with the complex internal cooling channels required for next-generation propulsion systems.

l Medical Device and Implant Manufacturing: The biocompatibility and wear resistance of advanced ceramics make them ideal for medical implants. Through precision Ceramic CNC Machining, manufacturers produce dental abutments, orthopedic joints, and surgical instruments with the complex geometries and micron-level precision required for biological integration. The application of ceramic CNC machining in medical devices ensures not only dimensional accuracy but also the surface quality necessary for tissue compatibility, with leading manufacturers reporting 99.5% success rates in clinical applications.

l Semiconductor and Optical Industries: In semiconductor manufacturing, high-purity alumina and aluminum nitride components machined with CNC precision handle wafer processing in corrosive environments. The exceptional dimensional stability of ceramics at varying temperatures ensures process consistency in lithography and etching equipment. Similarly, in optics, ceramic mirror mounts and lens barrels maintain alignment under thermal and mechanical stress, enabling advanced imaging systems for both scientific and commercial applications.

How Does Material Selection Impact the Success of Ceramic CNC Machining?

The optimal application of ceramic machining begins with proper material selection, as different ceramic compositions present unique machining characteristics and performance attributes.

1. Material Properties and Machinability Considerations

The hardness and fracture toughness of the selected ceramic directly influence tool life, surface quality, and economic feasibility. Alumina (Al₂O₃) offers an excellent balance of cost-effectiveness and performance, with Vickers hardness of 15-20 GPa making it suitable for many industrial applications. For more demanding applications, silicon nitride (Si₃N₄) provides superior fracture toughness but requires more sophisticated tooling strategies. Understanding these material-specific behaviors is essential for successful implementation.

2. Application-Driven Selection Criteria

The machining ceramic materials selection process must balance mechanical requirements, environmental conditions, and economic constraints. For high-temperature aerospace applications, zirconia-based ceramics offer the best thermal shock resistance, while for medical implants, the biocompatibility of alumina makes it preferable. In semiconductor applications, the electrical insulation and thermal conductivity of aluminum nitride (AlN) make it ideal for substrates and wafer chucks. Each material demands specific tooling and parameter strategies to maximize outcomes.

3. Pre-Processing and Blank Preparation

The quality of the ceramic blanks before machining significantly impacts the final result. Controlled pre-sintering to achieve specific density levels (typically 85-95% of theoretical density) optimizes the material for machining by reducing tool wear while maintaining sufficient strength for handling. Close collaboration with material suppliers to specify blank properties can improve tool life by up to 50% and enhance final component reliability through consistent material behavior during machining.

What Quality Control Measures Ensure Reliability in Ceramic CNC Machining?

The high-value applications of precision ceramic components demand rigorous quality assurance protocols that extend throughout the manufacturing process, from raw material to finished part.

1. In-Process Monitoring and Control

Advanced quality control systems integrate laser measurement and acoustic emission sensors to detect deviations in real-time. For critical aerospace components, this may include non-destructive testing methods like micro-CT scanning to verify internal integrity without damaging the part. The implementation of Statistical Process Control (SPC) charts for key parameters like surface finish and dimensional accuracy enables proactive adjustments before non-conformances occur, maintaining CpK values above 1.67 consistently.

2. Certification and Standard Compliance

Adherence to international standards like ISO 9001 certification provides the framework for consistent quality management. For medical applications, compliance with ISO 13485 ensures that all processes are validated and documented. These certification frameworks mandate regular audits, calibration of equipment, and thorough documentation, creating a system that reliably produces components meeting the most stringent industry requirements. Manufacturers with multiple certifications demonstrate a commitment to excellence that translates to customer confidence.

3. Final Inspection and Data Traceability

Comprehensive final inspection using coordinate measuring machines (CMMs) with temperature compensation verifies all critical dimensions against CAD models. For high-reliability applications, 100% inspection may be justified by the critical nature of the components. All inspection data is archived with full traceability to material batches, machine parameters, and operators, supporting root cause analysis if needed and providing customers with documented evidence of compliance.

How Can Engineers Optimize Designs for Ceramic CNC Machining?

Successful ceramic component design requires understanding the material’s capabilities and limitations, applying Design for Manufacturability (DFM) principles specifically tailored to advanced ceramics.

- Geometric Optimization Strategies: To avoid stress concentration and cracking, designers should eliminate sharp internal corners by incorporating radii of at least 0.5mm. Uniform wall thickness promotes consistent sintering and machining behavior, reducing distortion. For thin-walled structures, strategic ribbing can provide necessary stiffness without compromising the weight advantages of ceramics. These design optimizations can improve yields from 70% to over 95% while maintaining functional requirements.

- Design for Manufacturing (DFM) Principles: Implementing ceramic-specific DFM involves orientating features to minimize tool access challenges and designing fixturing surfaces early in the process. Standardizing tool-accessible geometries reduces machining time by up to 25% compared to complex, hard-to-reach features. For prototypes, designing with modular fixturing in mind accelerates iteration cycles, while production designs can optimize for dedicated fixtures that maximize stability and accuracy.

- Cost Optimization Through Design Intelligence: Intelligent design can significantly impact the economic feasibility of ceramic components. Specifying commercial-grade tolerances (±0.025mm) rather than precision tolerances (±0.005mm) where functionally acceptable can reduce costs by 30-40%. Similarly, understanding the cost drivers associated with different ceramic materials guides selection toward the most economical option that meets performance requirements. These design optimization strategies make advanced ceramics accessible for a broader range of applications.

Conclusion

Ceramic CNC Machining has emerged as a transformative technology that overcomes the limitations of traditional ceramic processing methods. Through digital precision control, specialized tooling strategies, and rigorous quality management, this approach delivers the micron-level accuracy and reliability required by the most demanding applications in aerospace, medical, and semiconductor industries. The combination of exceptional material properties with advanced manufacturing techniques enables engineers to design components that outperform those made from conventional materials. As this technology continues to evolve with improvements in tooling, software, and process monitoring, it will further expand the boundaries of what is possible with advanced ceramic materials.

FAQs

Q1: What is the typical cost of ceramic CNC machining compared to metal machining?

A: Ceramic CNC machining costs are generally 30-50% higher due to specialized diamond tooling and slower material removal rates. However, long-term benefits like extended component life and reduced maintenance often yield lower total cost of ownership. Volume production can reduce the premium to 15-25% with enhanced functionality.

Q2: Can ceramic CNC machining handle thin-walled structures?

A: Yes, with optimized toolpaths and fixturing, thin-walled structures down to 0.3mm are achievable. Techniques like trochoidal milling minimize stress on delicate features, ensuring yields over 95% for walls above 0.5mm. This makes ceramics viable for weight-sensitive applications like aerospace and medical devices.

Q3: How does ceramic CNC machining ensure design confidentiality?

A: Reputable manufacturers use encrypted file transfer, secure servers, and strict access controls. NDAs and project isolation in dedicated work cells are standard, ensuring intellectual property protection throughout the process. These measures prevent unauthorized access or leaks.

Q4: What are the lead times for small-batch ceramic CNC orders?

A: Standard lead times are 10-15 business days, depending on complexity and material availability. Expedited services can reduce this to 5-7 days for simpler parts. Early engagement helps plan for tooling or secondary process delays.

Q5: How does quality certification impact ceramic CNC machining outcomes?

A: Certifications like ISO 9001 ensure consistent processes, reducing defect rates below 2% and improving traceability. In regulated industries, this is mandatory and demonstrates commitment to quality and safety standards, leading to more reliable outcomes.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing, a company that helps engineers solve complex material challenges in sectors like aerospace, medical devices, and semiconductor equipment. With certifications including ISO 9001, IATF 16949, and AS9100D, the team delivers high-quality, cost-effective machining solutions. For a customized DFM analysis or project consultation, explore their custom CNC machining services to transform your ceramic component concepts into reality.